Deck Inspection: Checklist for Framing, Footings and More

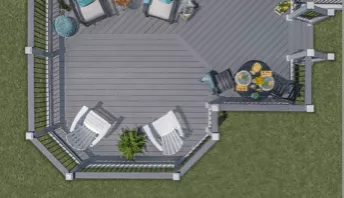

Your deck provides the foundation for your family’s outdoor entertainment and leisure activities, from cookouts and birthday parties to your favorite spot for Sunday morning coffee. That’s why it’s vital to ensure your deck is safe and up to current regulatory codes by performing routine inspections. With peace of mind that your deck is in solid working order, you’ll be able to get the most enjoyment from it.

On average, a professional inspection of the condition and strength of your deck’s guardrails should be scheduled every two years, and the deck surface should be cleaned at least annually to extend its lifespan and aesthetics. After all, just like your home, a deck undergoes high levels of stress throughout the year, including constant exposure to the elements, load-bearing situations and just normal wear and tear. The following deck inspection checklist is a good place to start.

Deck Safety: What to Look Out For

Your deck faces the harsh elements of the outdoors all year long. Being exposed to extreme heat and cold can take a toll on even the most well maintained decks. So, when you or a professional inspector check to see if your deck is up to spec, here are a few things to look out for regarding repairing your deck and its overall safety:

Insect Damage

Most modern-day decks are made of wood or composite that’s treated with chemicals to keep the bugs away. In some cases, including decks built before the 1980s, the wood isn’t treated with insect repellent, making it more likely for ants and termites to get into the framework and cause damage that can literally pull the deck away from the house.

You can check for this by noting whether your deck has any movement when you first step out onto it. If you notice a slight sway when you walk out, call a professional to come out for a thorough inspection and to check for insect vulnerabilities.

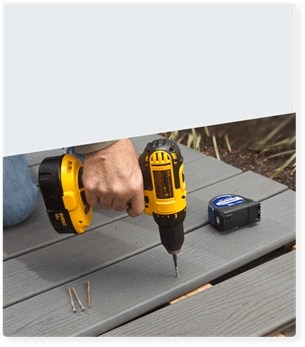

Rusted Fasteners, Connectors & More

One of the biggest factors in determining whether your deck is safe and sound is not outwardly visible. That’s why it’s important to look under your deck to ensure that fasteners, connectors and joists are all in good shape. That includes making sure that the nails, bolts, screws and other metal connector pieces aren’t rusted or otherwise compromised. If you detect rust, call an inspector.

Furthermore, it is highly recommended that any deck over 10 years old be inspected by a building professional with knowledge of current code. As building code evolves, new techniques and materials aimed at making sure decking projects are safe may need to be implemented.

Cracks & Rotting

It’s no surprise that after extended use, wood tends to crack. Small cracks aren’t anything to be alarmed about, as long as they don’t continue to grow. However, you do need to keep an eye on any cracks located around fasteners or between joists; these can exploit weaknesses in your deck and lead to serious problems down the line if not properly treated.

Regularly sealing and staining your deck every 2-3 years can help reduce cracking from water, cold and heat exposure. And if you do have a cracked floor board that keeps growing, replacing deck boards is your best safety option. The same tactic applies to wood deck rot. If you have a noticeable portion of boards that are rotting, you’ll want to replace those for both safety and aesthetics.

Remember, it’s your duty as a deck owner to regularly inspect your deck’s frame for safety vulnerabilities. Perform the “pick test” on deck posts to check for areas of decay or rot. If the wood slowly bends and doesn’t splinter much upon breaking, then you may have decaying wood that will need to be addressed.

Unsturdy Railing

If your railing is loose, fix it immediately. The risk for injury is simply too great for a railing repair to be put off. Railing is a critical area of the deck, and as mentioned above, it is important to ensure proper code-compliant construction techniques are employed. To ensure they remain sturdy, don’t allow anyone to sit or lean excessively on railings; after all, this is what deck furniture is for!

Mold & Mildew Exposure

Nearly every deck will develop a bit of a green tint from some mildew during its lifespan. Steps are the most susceptible to mildew growth, which can make them slippery and unsafe. Regular washing and staining will help prevent mildew growth. Mold and fungus, on the other hand, is nothing to take lightly. If you notice a fuzzy or mushroom-like growth, immediate attention is required as it could be a “tip of the iceberg” situation.

Deck Inspections

Deck Framing Inspection

Framing inspections are usually only required for decks that are built low to the ground to make it possible for inspectors to do their job without crawling under the structure. In these cases you will need to call for an inspection before the decking is installed so the framing is visible from above the deck. They will be verifying that you are building precisely what your plans indicated. Are you using the same size and type of wood as you specified? Is the joist spacing correct?

Inspectors will also be looking closely at the specific connections as they are assembled across the frame. They will want to see that you are using the proper joist hangers and they are not missing any fasteners. They will also be interested in seeing how well your beams are connected to your support posts.

Inspectors will be checking your framing to make sure it is consistent with your plans. They will be checking joist and beam spacing and all hardware connections.

When all your work is completed, you will also need to pass a final inspection before the permit can be closed. If you fail an inspection, you should be given a correction notice for what needs to be fixed before you can pass the inspection.

Deck Footing Inspection

Contractors can save a lot of time on a project by coordinating prompt footing inspections following excavations. Be sure to schedule the footing inspections before you start mixing and pouring the concrete foundations. Never pour concrete until after your footings have passed inspection.

In order to pass the footing inspection, you will need to have an inspector measure to verify that the base sizes and depths of the holes meet the specifications of the approved plans. The holes must also be free of loose dirt and water. If there is water in the holes, you may try to pump the water out or allow them to dry out over a couple of days. If you are not going to be able to attend the inspection, you will need to post the inspection card and approved plans in an accessible place for the inspector to sign. Once you have sign-off, on you can finish building your footings.

It’s important to note that you’ll want to continue to inspect your footings on a regular basis. As a primary part of your deck’s foundation, your footings secure and support your deck. In cases where footings are compromised, it’s most likely that they weren't large enough to support the deck in the first place. If you notice the concrete pour around your footings beginning to crack or pull up from the ground, then you should have a professional come out to perform a full inspection.

Profesional Deck Inspection Cost

Now that you’re familiar with the most important items on your deck safety inspection checklist, it’s time to talk about cost. A professional deck inspection cost typically ranges from as low as $25 for a 30-minute inspection to as high as $199 for a one-hour inspection, including a structural check, safety check and common building code violations check. After the inspection, you should receive a comprehensive written report with photos of any outstanding issues.

The longer you take good care of your deck, the longer you can enjoy it! That’s why there’s no substitute for the expertise of renowned professional deck inspectors like NADRA or Home Inspector to make sure your deck is up to par.

What If My Deck Fails Inspection?

Building a deck can be a pretty complicated project, and it’s not uncommon for experienced tradesmen and do-it-yourselfers alike to make mistakes or overlook details – that’s the whole point of an inspection. An inspector’s eye is trained to look for details that, many times, simply blend into the mix for the person who’s been working on the job day-to-day. So failing an inspection is not a horrible thing; it simply means your deck is going to be that much safer when completed.

Read over the inspection notice, or better yet, be on-site for the inspection. A quick conversation with the inspector can provide you with much more confidence in making corrections. Once the identified issues are resolved, call for a re-inspection. If you are unsure about any of the correction items listed, it is always best to contact the inspector for more information.

What is Dry Rot and How Can You Prevent Your Deck From Rotting?

Dry rot is a serious problem for wood decks because it compromises its structural integrity. Learn the signs and causes for deck rotting, as well as how to prevent or fix it, at Decks.com.

How to Avoid, Prevent & Repair Deck Joist Rot

Rotted deck joists can cause homeowners headaches. Learn more about how to avoid, prevent and repair deck joist rot at Decks.com.

Capped Composite Decking

What is capped composite decking? It's a great option if you like the look of wood but not the maintenance. Learn about capped composite at Decks.com.

Waterproof Decking Materials & Options

Did you know you can ensure the space under your deck stays dry, or even waterproof your decking boards? Explore all waterproof decking options at Decks.com.

How to Dry & Treat Wet Wood

Wet wood shrinks as it dries out and becomes less stable, which can cause it to check and warp. Learn how to dry out and treat wet wood at Decks.com.

More Helpful Resources

Explore Articles by Topic

Footings

Information related to installing frost footings for decks

Framing

Learn structural framing methods

Decking

Learn about wood and composite decking materials

Stairs

An in-depth look at the complex issue of how to build stairs

Railings

How to install guardrails and handrails to meet IRC code

Features

An overview on water drainage, benches, planters and lights

Design

The basics of deck design

Planning

Learn about permits and working with contractors

Porches & Patios

Build a covered deck to enjoy all seasons

Ledger

Proper attachment techniques

Care

Maintain your deck to maintain your investment

Materials

An overview on water drainage, benches, planters and lights

How to Remove Scuffs and Scratches from Composite Decking

Removing scuffs and scratches can help make your composite deck look like new. Learn how to fix and prevent your composite deck from future scratches.

How to Prepare & Protect Your Deck for Winter

Preparing and protecting your deck for the cold weather is important to ensure the longevity of your deck, especially in cold climates. Learn how to prepare your deck for winter at Decks.com.

How to Clean Outdoor Patio Cushions

Keeping your outdoor furniture cushions clean helps extend their life and makes your deck or patio area look nice. Learn how to clean outdoor cushions.

Is Trex Decking Worth the Investment? Expert Insights and Reviews

Discover why Trex decking is worth the investment. Learn about its durability, low maintenance, eco-friendliness, and the long-term value it adds to your home.

Waterproof Decking Materials & Options

Did you know you can ensure the space under your deck stays dry, or even waterproof your decking boards? Explore all waterproof decking options at Decks.com.

Pressure Treated Wood: Types, Grading Standards & More

Wondering if pressure treated wood is right for your project? Learn more about the different types of pressure treated lumber as well as how long they last at Decks.com.

Explore Articles by Topic

Footings

Information related to installing frost footings for decks

Framing

Learn structural framing methods

Decking

Learn about wood and composite decking materials

Stairs

An in-depth look at the complex issue of how to build stairs

Railings

How to install guardrails and handrails to meet IRC code

Features

An overview on water drainage, benches, planters and lights

Design

The basics of deck design

Planning

Learn about permits and working with contractors

Porches & Patios

Build a covered deck to enjoy all seasons

Ledger

Proper attachment techniques

Care

Maintain your deck to maintain your investment

Materials

An overview on water drainage, benches, planters and lights