Pressure Treated Wood: Types, Grading Standards & More

What is Pressure Treated Wood?

Pressure treated wood is lumber impregnated with a variety of preservative chemicals to prevent rot and insect infestation in exterior applications like decks and fences. Several species of wood can be treated, but a regionally available species usually predominates in any particular locale. Pressure treated lumber is ideal for outdoor construction as it has a long, useful life span and is much less expensive than alternatives.

How is Lumber Pressure Treated?

The treatment process involves placing a load of lumber in a huge cylindrical chamber called a retort with a door on one end that can be sealed airtight, and then forcing waterborne chemicals into the wood under pressure. The preservative chemicals are forced deep into the cellular structure of the wood and become part of the wood just as you see a colored transparent stain soak into and become part of the wood trim inside a home.

Once the raw wood is loaded into the cylindrical retort, a powerful vacuum is applied pulling the air out of the lumber and the retort. The retort is then flooded with the preservative chemicals and they’re drawn deep into the lumber like a magnet is attracted to iron. It’s not uncommon to raise the pressure inside the retort to over 150 pounds per square inch to drive the chemicals into the lumber.

After the chemical has been pushed into the lumber, it’s removed from the retort and set on a drip pad to capture the chemical preservative that leaks out of the lumber. This liquid is recycled and reused in the next batch. The lumber can’t be sold until all the excess chemical drips out. This may only take a few days in hot summer weather, but it can extend to two weeks in damp, cold winter weather.

How Long Does Pressure Treated Wood Last?

Treated wood can last more than 40 years. However, there are countless stories and photographs on the Internet showing failure of treated lumber in fewer than ten years. Treated lumber rated for ground contact can be partially destroyed by termites in less than five years.

There are many factors that weigh into why some treated lumber lasts longer than pieces that fail. It’s a good idea for you to keep the treated lumber around your house sealed as best as possible to prevent water from entering the wood, especially the end grain. Water fuels wood rot. Keep wood dry and it will not rot. It’s that simple.

If you need to bury treated lumber as you build a deck, playset, or outdoor shed, it’s a very good idea to surround the treated lumber posts with sand. You can purchase DIY termite treatment chemicals from many retailers. Mix up the solution as stated on the label and saturate the sand every few years as a preventative measure to keep termites away from the lumber.

Is Pressure Treated Wood Stronger?

The strength and properties of lumber from different species of wood varies considerably. Species like southern pine and Douglas fir are often used for deck framing. Both of these species are very strong. That said, strength varies according to the grade of the lumber. The strongest is Select, which is usually free of any knots. Number One grade is the next strongest. The higher the grade number the less strength it contains as knots in lumber are places where failure or cracks typically develop.

There are a handful of species commonly used for structural framing, and while relatively similar, their properties affect how far they can span as joists. Span tables will list species separately for this reason.

Types of Pressure Treated Wood

There are two primary types of pressure treated wood. The most common one you see in lumber yards and home centers is the type treated with water-based chemicals. Industrial and commercial customers such as electric utilities and railroads will purchase the second type of treated lumber that contains oil-based preservatives. You’ve likely noticed how electric poles and railroad ties under the steel rails look much different than the treated lumber that’s on your deck.

When it comes to treated lumber intended for use around the home, you’ll quickly discover when you read the print on the tag on the end of each piece how it’s supposed to be used.

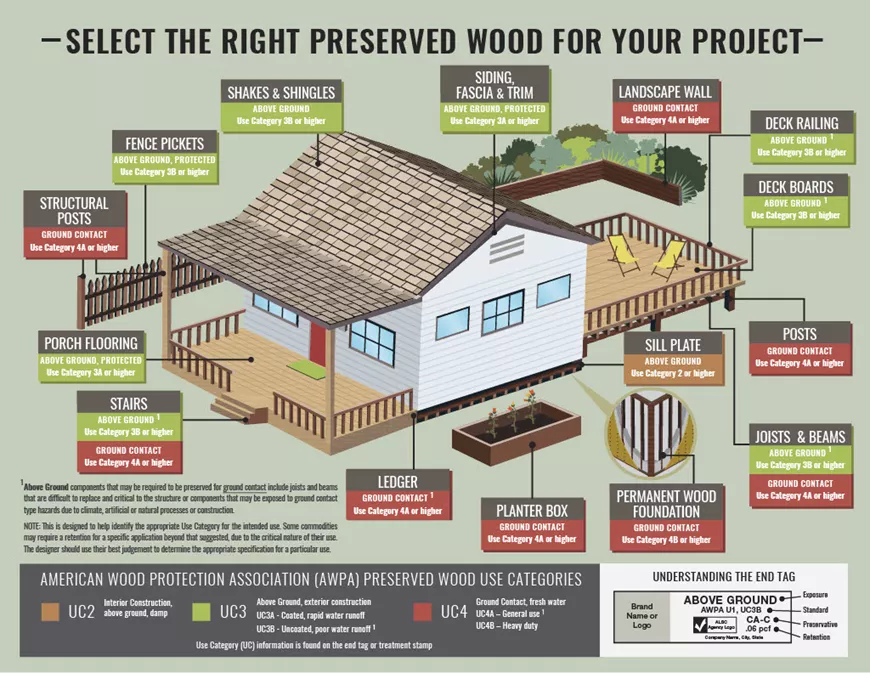

- Above Ground Use - this type should never contact the soil. UC2 classification is for interior use in damp locations. UC3 classification is for above ground exterior construction. UC3A is for coated treated lumber with rapid water runoff. UC4A is for use in uncoated situations with poor water runoff.

- Ground Contact - this type is made for ground contact. UC4 classification is for treated wood exposed to fresh water environments. UC4A is for general use. UC4B is for heavy-duty use.

There are many different chemicals used to treat lumber to prevent decay and to inhibit destruction by wood-boring insects. Here are a few common ones. Note that the more chemical that’s injected into the wood, the higher the protection. This weight is usually printed on the tag stapled to the end of each piece of treated wood. This is typically expressed on a label as pounds of preservative chemical per cubic foot of wood:

- ACQ - Alkaline Copper Quaternary (Type B or C)

- ACQ - Alkaline Copper Quaternary (Type A or D)

- CA-B - Copper Azole, Type B

- CA-C - Copper Azole, Type C

- Cu N-W - Waterborne Copper Naphthenate

Pressure Treated Lumber Grading Standards

Grade is a description of the quality of a given species. As lumber moves through a mill, grading inspectors review each piece and separate them onto different paths. Knots, decay, grain angle, wane, damage, warp and other physical characteristics of an individual piece of lumber distinguish it into a specific grade.

The grades provide a tighter presumption of the structural performance of each piece. A beat-up, decayed 2x8 covered in knots won’t be as strong as a clean, straight-grained one. Common grades, from worst to best, are utility and structural select. Span tables will also list grades in separate columns to further fine-tune the maximum allowable span.

Because treated wood is often still wet when it is delivered to the site, it will shrink slightly in width and thickness as it dries out. This can cause significant twisting, cupping, bowing and warping especially in lower-grade boards where knots and uneven grains are already present. It is possible that some boards will become so deformed that they will be unusable. You may want to store lumber by fastening boards together using a method called stickering to allow boards to dry evenly. You may also purchase kiln-dried after treatment (KDAT), which is much more stable, but also more expensive.

- Premium - Highest grade for ¾ radius edge decking.

- Select - The highest grade available, contains very few defects. It must meet a minimum 1/12-grain slope and have all knots sound encased. It has a high consistency and the appearance is very good.

- Number 1- Will contain no splits larger than the width of the board. Knots may not be larger than 2 ¾". One hole is permitted every 3 ft.

- Standard - Mid-range grade for 5/4 decking.

- Number 2 - Grain slope must meet minimum 1/8 grain slope. Boards will contain no splits larger than 1.5 times width of board. Knots may not be larger than 3 ½". One hole is permitted every 2 ft. Wane corners.

- Number 3 - The lowest-quality grade. Not suitable for deck construction.

Species & Sizes Of Pressure Treated Wood

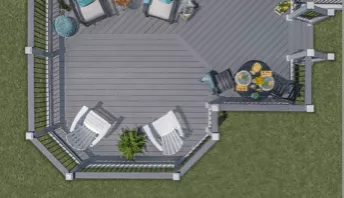

Treated wood is generally available as dimensional stock in 2x4s, 2x6s, 4x4s and 2x2s for rail components. 5/4x6s and 2x6s for decking. 2x8s, 2x10s and 2x12s for joists, stair stringers and beams. 6x6s for support posts and plywood.

The predominant species of treated wood is a regionally available softwood. Most common are:

- Southern Yellow Pine - Southern pine is the most common deck framing material in the eastern United States. It is strong and stiff. SYP logs yield a high proportion of sapwood, which works well to absorb preservative.

- Red and Ponderosa Pine - Less strong than SYP, found in northern U.S. and Canada.

- Douglas Fir – It is very strong and is less prone to warping and spitting than SYP. Predominant material found in western U.S. and Canada.

- Hem-Fir – It is weaker and more prone to warping and splitting than Douglas fir, but more receptive to preservation. It encompasses a group of western species.

Uses for Pressure Treated Wood

Different applications impose different hazards on wood, and require different amounts of preservative for protection. These amounts are called “retention levels,” referring to the amount of preservative retained in the wood after treatment. Furthermore, each preservative has its individual retention level for these applications. Be sure to obtain wood treated for the application you have in mind. The intended use is identified on the tag stapled to each piece of lumber.

From a homeowner’s perspective, you’d use pressure treated lumber in any situation where it’s likely the wood could get wet. Water is the enemy of wood as it provides the needed moisture that wood-destroying fungus requires to thrive and consume the wood.

You’d also use treated lumber in any building environment where wood-destroying insects are in abundance. It’s very common in tropical climates to use treated lumber for all the framing lumber in a house.

Cost of Pressure Treated Wood

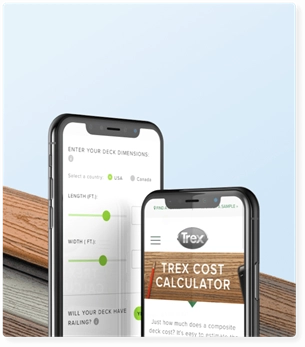

Supply and demand for building products can create unexpected cost increases. The cost of pressure treated wood is not immune from this economic reality. It’s often hard to predict rapid price increases. Labor shortages, supply-chain issues for preservative chemicals, transportation bottlenecks, etc., can all contribute to price increases. Price decreases happen, but they tend to be a much slower process as the retailers have to bleed off their higher-priced inventories.

If you’re worried about the price of treated lumber, you may want to look at the prices of composite decking. You can’t use composite lumber for the structural undercarriage of your deck, but it can be used for the decking and railing system. In certain instances, it might be a less-expensive alternative.

Ready to get started with your pressure treated wood project? Find a builder or retailer near you.

Capped Composite Decking

What is capped composite decking? It's a great option if you like the look of wood but not the maintenance. Learn about capped composite at Decks.com.

Pool Decking Options

When choosing a pool deck material, you should consider slip-resistance, heat absorption and more. Find the best material for your pool deck with Decks.com.

TimberTech

TimberTech Decking is manufactured by Timbertech Limited in Wilmington, OH.

Cutting a Concrete Pad

Learn how to use a concrete saw to cut a hole in a patio slab to install a deck footing.

How to Buy Concrete: Hiring a Ready-Mix Truck

Hiring a truck to deliver ready-mixed concrete for your project may make better sense than mixing it yourself. Learn how to order concrete for your deck at Decks.com.

Monolithic Pier

Compare the pros and cons of installing a solid concrete deck footing using a cardboard tube or engineered forms.

More Helpful Resources

Explore Articles by Topic

Footings

Information related to installing frost footings for decks

Framing

Learn structural framing methods

Decking

Learn about wood and composite decking materials

Stairs

An in-depth look at the complex issue of how to build stairs

Railings

How to install guardrails and handrails to meet IRC code

Features

An overview on water drainage, benches, planters and lights

Design

The basics of deck design

Planning

Learn about permits and working with contractors

Porches & Patios

Build a covered deck to enjoy all seasons

Ledger

Proper attachment techniques

Care

Maintain your deck to maintain your investment

Materials

An overview on water drainage, benches, planters and lights

Is Trex Decking Worth the Investment? Expert Insights and Reviews

Discover why Trex decking is worth the investment. Learn about its durability, low maintenance, eco-friendliness, and the long-term value it adds to your home.

Endeck

Endeck PVC decking is manufactured by Enduris Extrusions in Jacksonville, FL.

Rhino

Rhino composite decking is manufactured by Master Mark Plastics in Paynesville, MN.

How many footings do I need?

Learn how to determine the number of footings and support posts you need for your deck when designing your deck frame.

How to Buy Concrete: Hiring a Ready-Mix Truck

Hiring a truck to deliver ready-mixed concrete for your project may make better sense than mixing it yourself. Learn how to order concrete for your deck at Decks.com.

How to Install & Build Deck Footings

Learn how to install concrete footings to properly support your deck. Watch our step-by-step foundations video.

Explore Articles by Topic

Footings

Information related to installing frost footings for decks

Framing

Learn structural framing methods

Decking

Learn about wood and composite decking materials

Stairs

An in-depth look at the complex issue of how to build stairs

Railings

How to install guardrails and handrails to meet IRC code

Features

An overview on water drainage, benches, planters and lights

Design

The basics of deck design

Planning

Learn about permits and working with contractors

Porches & Patios

Build a covered deck to enjoy all seasons

Ledger

Proper attachment techniques

Care

Maintain your deck to maintain your investment

Materials

An overview on water drainage, benches, planters and lights