Wood and composite are the two most popular types of deck board material used to install on decks today. While both wood and composite decking can be fastened with screws through the top surface/face of the boards, each requires a specifically designed screw to ensure they stay safe and secure for decades. This article will explain the differences between wood deck screws and composite deck screws and provide some useful installation tips that will help make your next decking project a success.

What are Deck Screws?

The term “deck screw” refers to the specific type of screw used to hold deck boards securely to the joists. Deck screws are installed through the top surface of the deck boards. Sometimes, the type of screws used to secure structural deck components like joists, ledgers, and beams, are referred to as deck screws, but manufacturers and retailers typically refer to these types of fasteners as structural screws or exterior-grade construction screws. For the purposes of this article, “deck screws” will not refer to structural screws or the type of screws that work in conjunction with hidden fastener systems.

What are Wood Deck Screws?

Wood deck screws are made of steel and designed to hold wood deck boards securely to the deck joists. The two biggest threats to wood deck screws are the weather and the corrosive chemicals used to treat deck joists. The steel in stainless steel wood deck screws is formulated to be both weather and chemical resistant.

The steel in standard deck screws is protected with a zinc, paint, or polymer coating. Stainless steel screws are more expensive than standard wood deck screws, but both work fine under normal conditions. If wood deck screws will be exposed to salty air or water from the ocean, stainless steel is the better choice. Always confirm that the wood deck screws you choose are approved for use with treated lumber. To make the screw heads less conspicuous, most manufacturers of wood deck screws offer several colors to choose from.

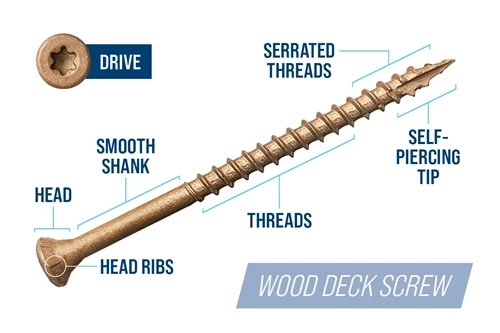

Parts of a Wood Deck Screw

All wood deck screws will have a head, drive, shank, threads, and a tip, but some screws will have additional components with specific functions designed for improved performance. Wood deck screws are available in various lengths from 1-5/8 in. up to 3-1/2 in., and most screws will have a #8 or #10 shank diameter.

- Head – The head of a wood deck screw is what holds the deck boards down in place.

- Drive – This recess or slot in the head allows a driver bit to grab hold of the screw and spin it down into the board. There are several different types of drives, each requiring a specific style bit.

- Head Ribs – These ribs help clear wood from the top of the board, allowing the head to be driven down flush with the top surface of the board while reducing the chance of distorting the area around the head or splitting the wood.

- Shank – The shank is the main body of the screw found between the head and tip.

- Smooth Shank – The smooth part of the shank is designed to slide freely through the deck board, allowing the head to pull the board down tight to the surface of the joist.

- Threads – Located on the shank, the helical shape of the threads is what pulls a wood deck screw down into the board and joist.

- Serrated Threads – These notches in the thread cut into the wood like saw teeth reducing the amount of torque required to drive in a screw.

- Self-Piercing Tip – Sharp, self-piercing tips help the threads grab hold of the wood faster, reducing wobble and the chance that the bit will slip out of the drive, potentially damaging the surface of the deck in the process.

Tips for Using Wood Deck Screws

While not all wood decking is the same thickness or made from the same type of wood, the process of installing wood deck screws is similar.

- If possible, choose a color that closely matches the color of your deck board finish.

- Install screws that will penetrate the joists about 1-1/2 in. Any less than that, and the threads may not stay securely fastened to the joist. And screws that are too long require so much torque that the heads are easier to strip, and the shanks are more likely to snap.

- Place the screws about an inch from the edge of the boards.

- Avoid stripping screw head drives by replacing driver bits at the first sign they are getting worn.

- Avoid splitting the wood by predrilling holes using a counter sink bit on knots, very hard or brittle wood, and when driving screws near the ends of deck boards.

- Use screws with a larger shank (#10) when installing wet or unseasoned wood because more narrow screws could snap when the boards shrink as they dry.

- Reduce trip hazards and the chance of injuries to bare feet by making sure the heads of the screws are installed just below the surface of the decking.

What are Composite Deck Screws?

Composite deck screws are specifically designed to hold composite deck boards in place without creating unsightly distortions in the surface of the decking. Like other exterior grade screws, composite deck screws will be made of either stainless steel or steel that is protected with a zinc, paint, or polymer coating. Stainless steel screws offer superior protection against rust and are the better choice when installing deck boards that will be exposed to salt spray from ocean water. Always confirm that the composite deck screws you choose are approved to use with treated lumber. Composite deck screws will be colored or have painted heads designed to match the color of the composite decking you’re installing.

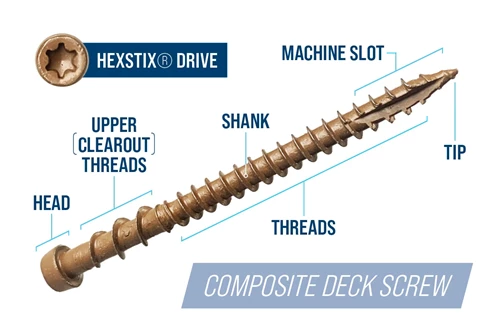

The Parts of a Composite Deck Screw

Not all composite deck screws are constructed the exact same way, and the names of the different components vary from one manufacturer to another. However, the majority of composite deck screws feature a smaller head and reverse top threads, the primary features designed to prevent surface distortion. The most common deck screws available will have a #10 diameter and a length of 2-1/2 in.

- Head – The smaller, reverse-tapered head on a composite deck screw is designed to hold deck boards in place without distorting the surface of the decking.

- Drive – This recess or slot in the head allows a driver bit to grab hold of the screw and spin it down into the board. There are several different types of drives, each requiring a specific style bit.

- Shank – The shank is the main body of the screw found between the head and tip.

- Upper (Clear Out) Threads – These reverse threads help clear excess material from the hole to make more room for the screw head, which also helps prevent distortions in the surface of the deck.

- Threads – Located on the shank, the helical shape of the threads is what pulls a composite deck screw down into the deck board and joist.

- Machine Slot – Precisely located machine slot cut which removes material while cutting.

- Tip – A sharp tip helps the threads grab hold of the wood faster, reducing wobble and the chance that the bit will slip out of the drive, potentially damaging the surface of the deck in the process.

Tips for using composite deck screws

- Only choose fasteners approved by the manufacturer of the deck boards you are installing. Premium deck manufacturers like Trex offer proprietary screws specifically designed to work with Trex composite deck boards.

- Choose a color that most closely matches the color of your deck boards.

- Install screws that will penetrate wood joists about 1-1/2 in. Any less than that, and the threads may not stay securely fastened to the joist. Screws that are too long require so much torque that the heads are easier to strip, and the shanks are more likely to snap.

- Place the screws about an inch from the edge of the boards.

- Avoid stripping screw head drives by replacing driver bits at the first sign they are getting worn.

- Use a 1/8 in. drill bit to predrill holes when installing a screw closer than 1 in. from the end or edge of a deck board.

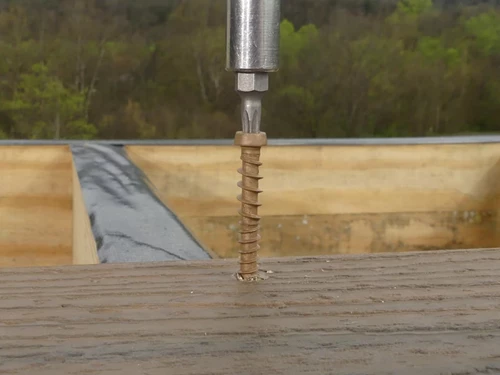

- Reduce trip hazards and the chance of injuries to bare feet by making sure the heads of the screws are installed just below the surface of the decking.

- Purchase a depth setting tool to achieve consistent screw depths.

- Some composite deck screws can be used in conjunction with plugs made from the same material as the deck boards, making the screws nearly invisible.

Can You Use Composite Deck Screws on Wood Deck Boards?

You should never rely on composite screws to hold wood deck boards in place because wood deck boards are not as structurally stable as composite decking. As soon as wood deck boards are installed, exposure to sun, moisture, freeze-thaw cycles, and pressure from foot traffic all begin to take their toll on the fibers in the wood. The diameter of the heads on composite deck screws is too small to hold wood deck boards in place.

Eventually, deterioration, the pressure from deflection, and the natural inclination for wood boards to twist, cup, and bow, can cause the boards to lift, sliding right past the screws that are still securely fastened to the joists. Loose deck boards don’t look good, can cause a trip hazard, will often creak when walked on, and could potentially reduce the integrity of your entire deck. The heads on wood deck screws have a larger diameter which is designed to prevent loose boards.

Why You Should Never Use Wood Screws on Composite Decking

Wood deck screws will hold composite deck boards in place just as well as composite deck screws, but they could drastically reduce the beauty of your deck. Because the fibers in wood deck boards are less densely arranged, when the large head of a wood deck screw penetrates the surface of the wood it simply compresses the wood fibers below it. However, because composite deck boards are made with much more dense material, that large a head on wood deck screws cannot compress the material below it. Instead, that material is pushed to the sides and upward causing an unsightly distortion, sometimes called mushrooming, on the surface. Composite deck screws are designed to hold composite deck boards in place for decades and are equipped with specific features that allow the heads of the screws to be driven down into composite deck boards without distorting the surface.