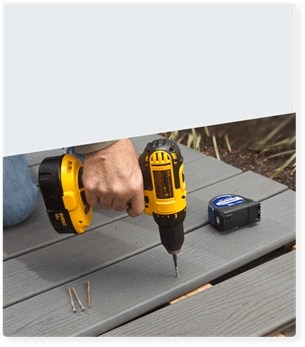

How to Dry & Treat Wet Wood

Most wood sold for deck building is considered wet and has a moisture content of over 30 percent water weight. Wet wood will shrink as it dries out and is less stable, which can cause it to check and warp. It also provides an environment where fungi and bacteria produce rot and insects thrive. Dry wood is lighter, easier to work with and less likely to split. You can buy lumber that has been kiln dried, but this will cost you a premium price. If you have purchased green or wet lumber, you should dry it out as best you can before working with it by stacking it on spacers and storing it in a shaded, dry and well ventilated area so the air can circulate evenly. You can check the moisture content by using a moisture meter at your lumberyard or cross cutting a board and examining the interior wood. Wood shrinks in all dimensions as it dries, but most problems are caused in how the boards handle the shrinkage in width and thickness.

Capped Composite Decking

What is capped composite decking? It's a great option if you like the look of wood but not the maintenance. Learn about capped composite at Decks.com.

Eco Friendly Composite & Wood Decking Options

Looking for the most environmentally friendly way to add a gorgeous deck to your home? Learn how composite decking is made from recycled materials at Decks.com.

Cutting a Concrete Pad

Learn how to use a concrete saw to cut a hole in a patio slab to install a deck footing.

Can I use pier blocks?

Our inspector explains the pros and cons of using pier blocks for deck foundations.

Layout Deck Foundations

Learn how to lay out your deck footings accurately using triangulation with our step-by-step instructions.

More Helpful Resources

Explore Articles by Topic

Footings

Information related to installing frost footings for decks

Framing

Learn structural framing methods

Decking

Learn about wood and composite decking materials

Stairs

An in-depth look at the complex issue of how to build stairs

Railings

How to install guardrails and handrails to meet IRC code

Features

An overview on water drainage, benches, planters and lights

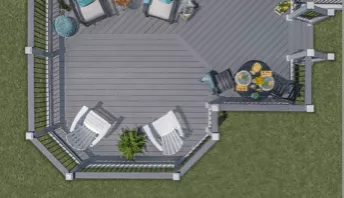

Design

The basics of deck design

Planning

Learn about permits and working with contractors

Porches & Patios

Build a covered deck to enjoy all seasons

Ledger

Proper attachment techniques

Care

Maintain your deck to maintain your investment

Materials

An overview on water drainage, benches, planters and lights

Is Trex Decking Worth the Investment? Expert Insights and Reviews

Discover why Trex decking is worth the investment. Learn about its durability, low maintenance, eco-friendliness, and the long-term value it adds to your home.

Rhino

Rhino composite decking is manufactured by Master Mark Plastics in Paynesville, MN.

UltraDeck

UltraDeck encapsulated composite decking is manufactured by Midwest Manufacturing Extrusion in Eau Claire, WI.

How many footings do I need?

Learn how to determine the number of footings and support posts you need for your deck when designing your deck frame.

Protecting From Collapse

Learn how to use cardboard sonotubes and hole covers to protect your deck footing holes from caving in and flooding before pouring concrete.

Water in deck footing holes

Find out what to do if your deck footing holes fill up with water.

Explore Articles by Topic

Footings

Information related to installing frost footings for decks

Framing

Learn structural framing methods

Decking

Learn about wood and composite decking materials

Stairs

An in-depth look at the complex issue of how to build stairs

Railings

How to install guardrails and handrails to meet IRC code

Features

An overview on water drainage, benches, planters and lights

Design

The basics of deck design

Planning

Learn about permits and working with contractors

Porches & Patios

Build a covered deck to enjoy all seasons

Ledger

Proper attachment techniques

Care

Maintain your deck to maintain your investment

Materials

An overview on water drainage, benches, planters and lights