Common Wood Defects: Types & Causes of Lumber Issues

There are few if any, perfect pieces of lumber. In fact, most lumber has defects, and it’s important to become familiar with the different types of wood defects—and how they can affect appearance and performance—when you’re building a deck.

Defects in lumber can develop as trees grow or after they’re harvested and processed. All lumber is graded for quality, and the first step in avoiding lumber defects is to purchase higher-grade materials at the outset.

Allowing the wood to dry properly before installing it also helps, especially when using pressure-treated lumber. For deck boards, applying protective stains can not only conceal visual defects but also prevent or limit the progression of defects such as checking by slowing the drying process.

Types of Natural Wood Defects in Deck Boards

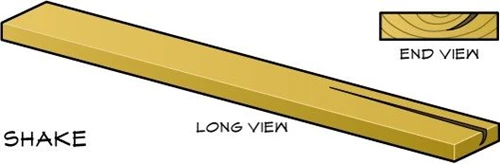

Warping

Warping is any variation from a true plane surface on a piece of lumber. This occurs due to differences in the radial, tangential and/or longitudinal shrinkage of wood or when residual growth stresses contort the board.

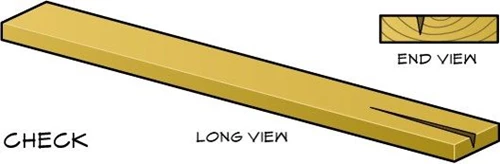

Checks and Splits

A check refers to a surface crack within the board, usually running lengthwise. The most common cause is the lumber drying too quickly. Checking allows water to enter the board beyond the pressure-treated surface and can accelerate the decay of the board.

Splits, unlike checks, run all the way through the board and a severe split can make it useless. Sometimes split boards can be ripped or cut to salvage a portion of it.

Pecking

Pecking is most common in cypress. It appears on lumber as a dark shallow cavity or pitted area and occurs due to the action of a parasitic fungus. The decay stops after the tree is cut. Many woodworkers seek out “pecky” or “peggy” cypress for the visual appeal of its unusual textured surface.

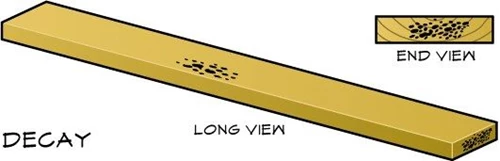

Rot and Decay

Rot is a common form of decay that refers to the disintegration of the wood fiber and is caused by microscopic organisms like mold and fungus that feed off the wood. Fungi require four conditions to thrive: oxygen, temperatures of 40° to 100°F , moisture (30% or more thrive), and a food source (wood).

Woods like cedar and redwood contain natural “extractives” that make them resistant to rot. Pressure-treated wood is invested with chemicals toxic to fungus and molds. Many stains have mildew inhibitors to help prevent decay. The best way to avoid decay is to keep your deck dry before and after it’s installed.

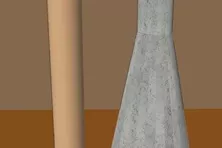

Pith

Pith is the spongy center of the tree and it becomes a defect when it appears on the board surface. Pith has the girth of a pencil, about a ¼ inch in diameter. The first three or four growth rings around the pith also should be treated with caution. As these sections dry out, they can open up and curl at the edges. You might be able to cut out this portion of the board and use it.

Ring Shake

Ring shake refers to cracks that appear between and parallel to the tree's growth rings. This weakens the wood. Dark discoloration and an unpleasant vinegar or rancid odor may also be present This defect stems from parasitic bacteria and is most prevalent in wood with a high moisture content.

Streaks

Some boards are discolored by streaks, commonly referred to as mineral streaks. This happens when dark-colored minerals are drawn into the tree from its water source or when mold grows. The streaks are generally blue or brown and can be cut out or concealed with a dark stain. Cleaners containing oxalic acid can remove streaks caused by mold.

Insect Damage

Many insects feed on wood and make their home there. Beetles, moths, and wasps are common, as are borers, which are often "secondary invaders" attracted to wood already weakened, damaged or dying.

Wood-boring insects produce sawdust-like “frass” (excrement). Their holes are usually round and scattered randomly across the wood. Wood that exceeds 30% moisture content attracts the insects.

Pitch, Gum and Sap

These resinous substances, natural elements of trees, can gather in pockets in a board, typically in an area where the tree was injured. Resin and sap can stain lumber and may cause difficulty when applying finishes.

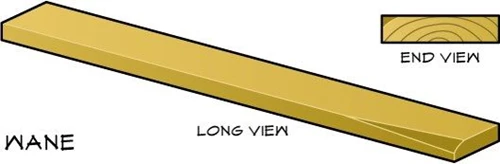

Wane

Wane refers to the presence of bark or the absence of wood at a board’s corners. Wane is found only in lower-grade lumber. In some cases, you can simply flip the board to conceal this defect.

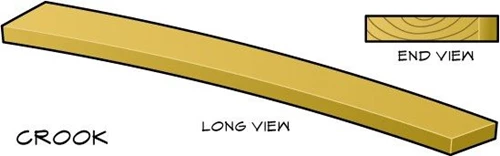

Crook or Crown

A crook or crown is a defect in which the board is bent end-to-end. It can occur from uneven drying or if the trees piths at the edge of the board. You may be able to rip the board to recover a narrower straight board, or you can try passing it through a jointer several times. Anytime you're removing the outer perimeter of a pressure-treated board used in deck construction, be sure to apply an approved topical chemical treatment to the edge or ends

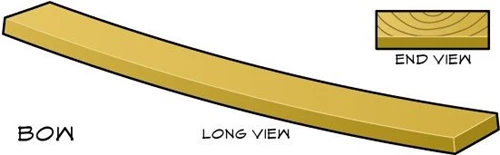

Bowing

Bowing refers to a defect in which the board bends along the grain lines (but not across them). If the board were laid across a flat surface, both ends would be in the air. This defect can be caused by uneven air circulation as the wood dries. The internal stresses of bowed boards make them difficult to cut, and ripping a bowed board can be dangerous. When making a crosscut, face the bow upward.

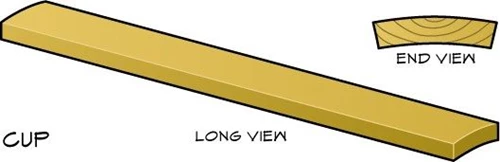

Cupping

Cupping occurs when the board bends edge-to-edge across its face, forming a U-shape. It is common in boards that are cut close to the pith. Cupped boards can be ripped into smaller boards and planed. Forcing it flat will likely cause a cupped board to cracking.

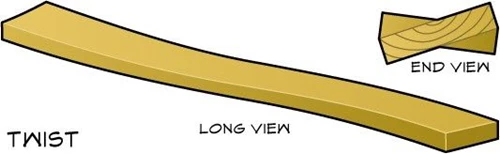

Twisting

Twisting is a general term for a board that bends in any combination of directions and cannot maintain a straight line. Sometimes one corner doesn’t line up with the others. It usually occurs when the wood grain pattern is not parallel to the edge.

Knots

A knot is a defect in a piece of wood caused by the presence of a branch. When grading lumber, knots are classified by their size, form, and soundness (how well they’re held in place). Knots are not only unattractive, but they also can weaken the board and/or serve as the starting point for checking. The higher the grade of lumber, the fewer and smaller the knots. The higher the grade of lumber, the fewer and smaller the knots. The higher the grade of lumber, the fewer and smaller the knots.

- Dead or Loose Knot - As a tree grows, lower branches die off and get surrounded by subsequent growth. Dead branches produce knots that are not attached to the wood and are the most likely to fall out.

- Tight or Closed Knot - A tight knot has a flat face free of openings on the board’s surface and doesn’t affect the wood's strength. This type of knot is produced from a living branch.

- Spike Knot - A spike knot is an elongated knot that occurs when the wood is cut more or less parallel to the length of a knot (branch).

- Pin Knot - A knot that is less than ½ inch in diameter. These small knots are usually sound and less visible. They may be present in some higher grades of wood.

Types of Manufacturing Wood Defects in Deck Boards

These lumber and deck board defects are caused by sawing and dressing the lumber, which can stress the wood.

Roller Check

Roller check occurs when a cupped board is mechanically flattened between roller planes. A light roller check is up to 2 feet long, a medium roller check is between 2 and 4 feet long and heavy roller check is more than 4 feet long.

Skip

Skip is referred to as any area where the planer missed the surface, leaving it rough. Skip occurs where the board is too thin for the planer knives to reach the surface and remove all the rough areas.

Machine Burn

Machine burn is the visible darkening of wood due to overheated knives and/or blades, usually because they are dull. This defect can usually be removed by sanding.

Choose Your Decking Material & Get Started Building Your Deck Today

Selecting high-grade boards is the first step in avoiding defect-prone lumber. Your next line of defense is identifying the defects you find and determining whether they’ll affect your deck’s appearance and performance. With a little practice, you’ll quickly develop a sense of which defects matter and which don’t.

Defect-free: The case for composite deck boards

Another option for minimizing lumber defects is to use composite deck boards instead of wood. They cut and fasten like wood but don’t share wood’s natural or machine-made imperfections because manufacturers use tightly controlled processes and top-grade ingredients. Composite decking also requires much less time and money to maintain than wood and lasts longer. Compare composite vs wood here.

Use our online tools to search for local suppliers of composite decking and to find a contractor in your area who can install it for you.

Capped Composite Decking

What is capped composite decking? It's a great option if you like the look of wood but not the maintenance. Learn about capped composite at Decks.com.

How to Read Lumber Grade Stamping

Any lumber you purchase should have a grade stamp, which provides info about the characteristics of the wood. Learn how to read lumber stamps at Decks.com.

Waterproof Decking Materials & Options

Did you know you can ensure the space under your deck stays dry, or even waterproof your decking boards? Explore all waterproof decking options at Decks.com.

Cutting a Concrete Pad

Learn how to use a concrete saw to cut a hole in a patio slab to install a deck footing.

Monolithic Pier

Compare the pros and cons of installing a solid concrete deck footing using a cardboard tube or engineered forms.

Can I reuse existing footings

Our inspector discusses the topic of reusing footings for a new deck.

More Helpful Resources

Explore Articles by Topic

Footings

Information related to installing frost footings for decks

Framing

Learn structural framing methods

Decking

Learn about wood and composite decking materials

Stairs

An in-depth look at the complex issue of how to build stairs

Railings

How to install guardrails and handrails to meet IRC code

Features

An overview on water drainage, benches, planters and lights

Design

The basics of deck design

Planning

Learn about permits and working with contractors

Porches & Patios

Build a covered deck to enjoy all seasons

Ledger

Proper attachment techniques

Care

Maintain your deck to maintain your investment

Materials

An overview on water drainage, benches, planters and lights

Is Trex Decking Worth the Investment? Expert Insights and Reviews

Discover why Trex decking is worth the investment. Learn about its durability, low maintenance, eco-friendliness, and the long-term value it adds to your home.

Capped Composite Decking

What is capped composite decking? It's a great option if you like the look of wood but not the maintenance. Learn about capped composite at Decks.com.

Differences Between PVC & Composite Decking

Both PVC and composite materials can be a great alternative to traditional wood decking. Learn the pros and cons of each material with our full comparison.

How many footings do I need?

Learn how to determine the number of footings and support posts you need for your deck when designing your deck frame.

Footing Size

You don’t need to be an engineer to figure out what size footings your new deck will need to safely support it. Everything you need to know is right here.

Can I reuse existing footings

Our inspector discusses the topic of reusing footings for a new deck.

Explore Articles by Topic

Footings

Information related to installing frost footings for decks

Framing

Learn structural framing methods

Decking

Learn about wood and composite decking materials

Stairs

An in-depth look at the complex issue of how to build stairs

Railings

How to install guardrails and handrails to meet IRC code

Features

An overview on water drainage, benches, planters and lights

Design

The basics of deck design

Planning

Learn about permits and working with contractors

Porches & Patios

Build a covered deck to enjoy all seasons

Ledger

Proper attachment techniques

Care

Maintain your deck to maintain your investment

Materials

An overview on water drainage, benches, planters and lights