The Ultimate Guide to Composite Decking Profiles

Along with the fun of selecting your new composite deck's design, color, and surface finish, you also decide on a decking profile. Your decking profile helps determine your deck's strength, design, installation method, and project cost.

We'll guide you through the diverse board profiles, ensuring you make the best choice. Choosing the right composite decking profile will impact your project both during installation and throughout its lifespan. Dive into our comprehensive guide to learn more.

Comparing Composite Decking Profile Options

A composite decking profile refers to the cross-section of a decking board or its ends. Depending on your decking project requirements, you’ll have a selection of profiles to choose from. These include solid, scalloped, and grooved profiles. Here’s a closer look at each to help you find your perfect match.

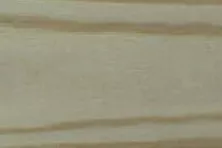

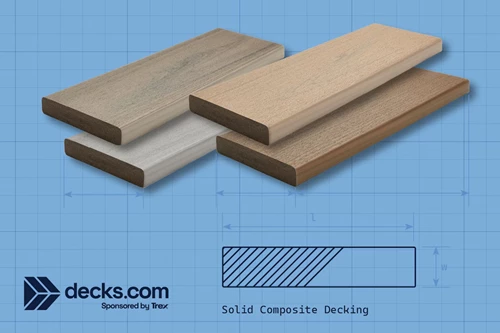

Solid Composite Decking

A solid composite board, such as the Trex Select Composite Decking comes in both square-edge and grooved-edge profiles. Solid profile decking will flex less than scalloped deck boards, and what else?

Pros of Solid Composite Decking Profile

- Higher rigidity

Cons of Solid Composite Decking Profile

- Heavier

- Higher costs due to more material and shipping

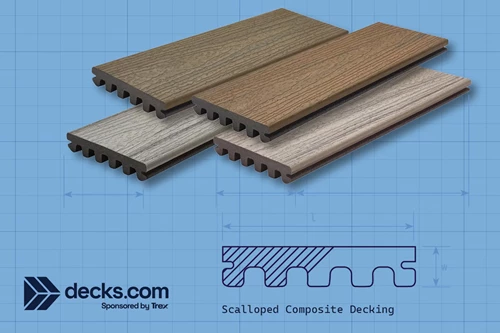

Scalloped Composite Decking

Scalloped profiles have slots on the underside of the material that runs the entire length of the board. This reduction in material makes for a lighter board that’s easier to handle. The top-side surface looks like solid decking, and scalloped profile decking is more affordable because there is less cost for material and less cost to ship.

While most decks will benefit from picture frame boarder boards or a raised fascia board that hides the cut ends of composite decking, this is particularly important for decks made with scalloped deck boards, because the end profiles are particularly conspicuous.

Another benefit of scalloped boards is that the space between the joist and deck board dries faster after a rain, which can extend the life of both. However, installing a protective joist membrane tape is still advised.

Pros of Scalloped Composite Decking Profile

- Reduced weight

- Reduced material cost

- Topside aesthetic similar to solid decking

- Quicker drying time for the top surface of the joists below

Cons of Scalloped Composite Decking Profile

- Conspicuous end-of-board profile

- Less stiff than solid profiles

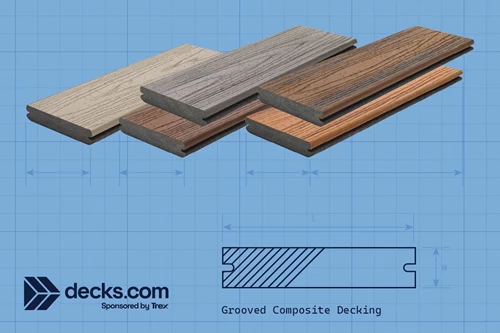

Grooved Composite Decking

Aptly named for the grooves that run down the lengths of the decking board, grooved composite decking can be applied to solid or scalloped decking boards and allows side fasteners rather than top fasteners. The grooved composite decking board design allows hidden fasteners, such as the Trex Hideaway Collection, to secure the decking boards to the frame without the need to screw through the material or have the fasteners visible. Combined with a much cleaner installation, grooved composite decking is a popular choice regardless of solid or scalloped profiles.

On the downside, the hidden fasteners and grooves will be visible when finishing the edge of the deck. Most installers opt for a solid profile board and top-side fastener to complete the deck edges.

Pros of Groove Composite Decking

- Available in solid & scalloped profiles

- Fasteners out of sight

- Quicker installation

Cons of Grooved Composite Decking

- Installation requires special fasteners

Hollow Composite Decking

Hollow composite decking contains holes throughout the length of the decking material. These holes dramatically reduce the board's weight and the raw materials needed to produce it, resulting in a low-cost product. Additionally, the reduced weight makes handling and installing hollow composite decking much easier.

However, professional installers and manufacturers generally agree that most hollow composite decking does not meet deck structural requirements. You’ll find that major reputable manufacturers do not offer this particular profile within their product range. That isn't to say every hollow composite board is of poor quality, but we here at Decks.com strongly advise you to seek professional advice before selecting a hollow board. Issues such as water, insects, and vegetation entering the cavities will quickly degrade the material, making it no longer fit for purpose.

Pros of Hollow Composite Decking

- Low cost

- Lightweight

Cons of Hollow Composite Decking

- Weak material

- Hollow areas hold unwanted materials

- Quicker degradation

- Unlikely to meet deck structural requirements

- Boards may be damaged when face fastening is installed

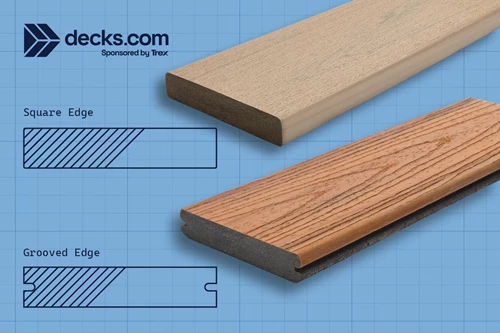

Grooved vs. Square Edge Decking: Which Is Better?

While both grooved edge and squared edge decking boards are solid and sturdy, the main difference between them is in the installation method. Grooved edge boards require hidden fasteners, and not all brands of hidden fasteners will work with all grooved edge boards. Trex's Universal Fasteners offer a one-step solution using the Universal Fastener Installation Tool to provide a seamless, polished look.

Square edge boards, on the other hand, are installed with traditional deck screws, which are inexpensive and almost universal. The downside of square edge boards is that the screws may be visible. You can purchase special decking screws with color-coordinated caps to conceal the screw placement, but this will add to the cost. Ultimately, the choice between square edge and grooved edge decking boards depends on which installation method you prefer.

What to Look For (and What to Avoid) When Buying Composite Decking Boards

Choosing the right composite decking board for your project will make all the difference to the end result. Take the time to deliberate over the following factors when developing your composite decking design and selecting a decking board.

Factors to Consider When Selecting a Composite Decking Board

Deck Purpose

The purpose of your deck plays an important role in selecting the appropriate product. For example, a boat dock is likely to sustain heavy loads compared to a patio seating area. It helps to have a clear idea of your deck’s intended use to decide on the strength of your boards.

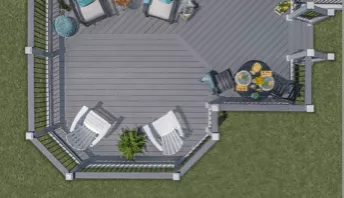

Deck Design

With the development of composite decking, there are new design possibilities. You can design a deck that combines several color shades and even curving material. Decks no longer need to be linear; they can incorporate curved patterns and structures. If this is something that appeals to you, you'll need to consider whether specific composite deck boards can accommodate your design.

Deck Size

Size matters, especially when it comes to cost and type of material you’re interested in. Manufacturers such as Trex Decking offer a range of material lengths that will affect your deck's overall design. Picking the appropriate length material means you’ll be able to control waste and joints.

Material Availability

Is the material you want readily available? This isn’t usually a problem with large, reputable manufacturers. But if it needs to be customized or specially ordered, factor in the waiting time in your project timeline.

Material Batches

Composite decking is manufactured in batches - an important note when ensuring the color between packs of decking material matches. To be safe, the material should be purchased in a group batch to avoid color variation. Again, for large manufacturers such as Trex, this isn’t a concern. However, lower-quality products can present issues with mismatching colors.

Availability of Additional Material & Products

Finishing off your deck requires accessories, such as fascia boards and railing systems. It makes sense to consider a manufacturer that can provide you with items that perfectly match your decking boards in terms of color and quality.

Cutting the Composite Material

Composite decking is designed to be cut to length. However, there are occasions when material needs to be ripped along its length. For example, if you intend to face dock piles with one-inch composite strips, you would need to use a solid profile. Using any other profile would expose the profile's scallops, grooves, and hollows.

Product Warranty

Finally, before you begin constructing your new composite deck, you should check the warranty of the composite decking material for its duration and coverage. There can be a huge difference in warranties between manufacturers, even down to particular low-quality manufacturers offering no warranty at all.

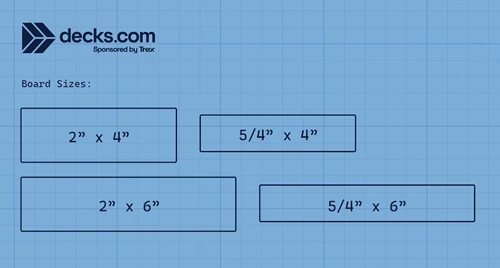

What Size Deck Board Do I Need?

While you can usually order any length board directly from manufacturers like Trex as long as you buy at least a truckload, retailers will not sell boards at lengths other than 12-, 16, or 20-foot lengths. When designing your deck, it’s best to avoid boards running end-to-end to reach long distances. Incorporate a change in the direction of the boards to prevent weak and hazardous butt joints. With careful planning and design, you can calculate decking material to dodge such problems.

How Wide Are Deck Boards?

Composite deck boards are available in widths ranging from 4 to 6 inches. You can let your imagination run wild and fit in boards of varying widths for a one-of-a-kind design. However, it should be noted that the smaller the board, the more you'll need to cover your deck area. Be mindful of the dent to your budget if you opt for the lower side of the scale.

How Thick Are Deck Boards?

The standard thickness of a composite decking board is one inch. Some manufacturers produce two-inch boards for commercial and 7/8-inch boards for residential applications.

Choosing the Right Composite Decking Board: Which Decking Profile is Best?

When picking a composite deck board, you’ll typically have a choice between solid and scalloped, with the option of grooves. As we’ve highlighted, the differences come down to performance and cost. However, the true deciding factor is the actual design of your new composite deck.

Still unsure of what to choose? Answer our series of questions to help you select the ideal composite decking board for your project. This should give you a clearer picture of the deck that will add the perfect touch to your home.

- Is the weight of the decking a concern?

- Will you want curves in the deck?

- Will you see the profile of the boards?

- Do you want to hide the fasteners?

- What length of boards do you need?

- What thickness of boards do you need?

- What width of boards do you need?

- What color do you desire?

- Will you want railing?

- Can you source the right material?

- Do you want a 50-year or 25-year warranty?

Learn More About Composite Decking

Capped Composite Decking

What is capped composite decking? It's a great option if you like the look of wood but not the maintenance. Learn about capped composite at Decks.com.

Pressure Treated Wood: Types, Grading Standards & More

Wondering if pressure treated wood is right for your project? Learn more about the different types of pressure treated lumber as well as how long they last at Decks.com.

Fence Post Spacing: How Far Apart Should Fence Posts Be?

Spending a little more time and effort up front on determining the best fence post spacing for your deck project, could save you a bunch of time and money when it comes time to build it. Here’s how to do it…

Cutting a Concrete Pad

Learn how to use a concrete saw to cut a hole in a patio slab to install a deck footing.

Retaining Walls

Avoid problems related to digging deck footings near retaining walls. Learn some tips from the pros for how to handle these difficult situations.

Water in deck footing holes

Find out what to do if your deck footing holes fill up with water.

More Helpful Resources

Explore Articles by Topic

Footings

Information related to installing frost footings for decks

Framing

Learn structural framing methods

Decking

Learn about wood and composite decking materials

Stairs

An in-depth look at the complex issue of how to build stairs

Railings

How to install guardrails and handrails to meet IRC code

Features

An overview on water drainage, benches, planters and lights

Design

The basics of deck design

Planning

Learn about permits and working with contractors

Porches & Patios

Build a covered deck to enjoy all seasons

Ledger

Proper attachment techniques

Care

Maintain your deck to maintain your investment

Materials

An overview on water drainage, benches, planters and lights

Is Trex Decking Worth the Investment? Expert Insights and Reviews

Discover why Trex decking is worth the investment. Learn about its durability, low maintenance, eco-friendliness, and the long-term value it adds to your home.

Evergrain

Evergrain composite decking is manufactured by Epoch Composite Products in Lamar, MO.

Different Types of Joist Hangers

You can use joist hangers to strengthen your deck. Learn more about the different types of joist hangers for you to use on your decking project at Decks.com

How many footings do I need?

Learn how to determine the number of footings and support posts you need for your deck when designing your deck frame.

Prevent Deck Sinking

Sinking deck footings can lead to serious problems. Learn what can cause concrete footings to sink. Properly installed footings will resist sinking.

Can I use pier blocks?

Our inspector explains the pros and cons of using pier blocks for deck foundations.

Explore Articles by Topic

Footings

Information related to installing frost footings for decks

Framing

Learn structural framing methods

Decking

Learn about wood and composite decking materials

Stairs

An in-depth look at the complex issue of how to build stairs

Railings

How to install guardrails and handrails to meet IRC code

Features

An overview on water drainage, benches, planters and lights

Design

The basics of deck design

Planning

Learn about permits and working with contractors

Porches & Patios

Build a covered deck to enjoy all seasons

Ledger

Proper attachment techniques

Care

Maintain your deck to maintain your investment

Materials

An overview on water drainage, benches, planters and lights