How to Replace Deck Boards & Repair Your Deck

As your wood deck ages, the boards may begin to rot, split, or come loose. This is especially true if the deck boards have not been properly maintained with routine cleaning, staining, and sealing. Repairing deck boards may be as simple as tightening some screws, but rotted deck boards or split boards should be replaced. This is an easy DIY project that doesn’t require a permit or, in most cases, rebuilding the deck’s structure, because posts and joists aren’t directly exposed to the elements and often outlast the decking. You’ll save a lot of time and money by replacing only the worst deck boards instead of the whole deck.

How Much Does It Cost to Replace Deck Boards?

If the deck was damaged by a storm, your homeowner’s insurance might cover the cost of deck repair or replacement.

The cost of replacing deck boards depends on how many boards you replace and the cost of the wood you use. A single pressure-treated 5/4 (1-5/32-inch) deck board measuring 6 inches wide and 16 feet long will cost around $23. The same deck board in cedar will be about $58, while a similar composite deck board runs about $42. A 5-pound box of #10 3-1/2-inch coated deck screws (approx. 240 screws) costs around $27. The same screws in stainless steel cost nearly twice as much.

Required Tools

- Circular Saw / Jigsaw / Oscillating Multitool / Reciprocating Saw

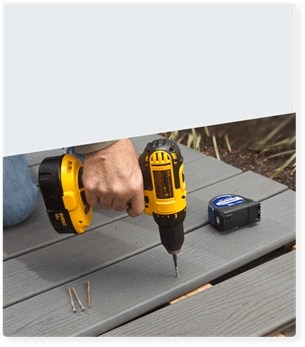

- Screw Gun / Power Drill

- Speed Square

- Wood Chisel

- Claw Hammer

- Pry Bar / Cat’s Paw

- Eye Protection

- Paint Brush

- Tape Measure

- Pencil

Required Materials

- Replacement Deck Boards

- Coated or Stainless Steel Deck Screws

- Wood Sealant / Stain (only for use on wood decking)

The new deck boards should match the look of what’s already on your deck. If you’re unsure of the wood species used, make a fresh cut and smell it. Pressure-treated lumber, cedar, and redwood have their own distinct aromas. For composite decking, try to identify the manufacturer or brand and then match the color and style on the company’s website or at retail.

How to Remove Deck Boards & Replace Them

Remove the Bad Boards from the Deck

Identify the deck boards to replace. If you’re not removing the entire board, decide where to make cuts. Offset the cuts at least one joist space from the end of neighboring boards and make sure that the remaining portion of the old deck board, if any, and the new board will span at least two joist spaces. Mark the cut line using a pencil and speed square. Cut out the damaged deck board either flush with joist or along the joist’s centerline using a circular saw. To avoid cutting notches into the neighboring boards with the circular blade, use a jigsaw or oscillating multitool to finish the cut. If you cut along the centerline of the joist, remove any nails or screws from the cutline or shift the cutline to avoid them.

When using a pry bar to remove a board, place a block of wood under it so it won’t mar adjacent deck boards. If you cannot remove a screw because the head is stripped, use an oscillating multitool or reciprocating saw to cut the screw flush with the joist. Use a cat’s paw to extract deeply sunk nails or cut them.

Inspect the Joists, Beams, and Posts

Removing the deck boards will expose the joists and beams. Inspect them for rot or other damage and verify that they’re fastened securely to the posts and ledger board. Inspect the joists for rot, too, especially if they contact the ground. Verify that the joist hangers are plumb, free of rust, and not missing any fasteners. If you find rot in any structural member, decide whether to repair or replace it and learn how to avoid and prevent rot in the future.

Add Support Cleats & Reinforcing Joists

If necessary, add cleats or sister joists to support the replacement deck boards and to reinforce damaged joists. Fasten the cleat/joist using framing nails or structural screws at the existing joist where you cut off a deck board and anywhere that a joist needs reinforcement. Make sure the top of each cleat/joist is flush with the top of the existing joist. Apply a sealer to the top of the joists to help them resist rot.

Cut the New Deck Boards

Measure the distance between existing deck boards. If possible, use a single board to span the distance and allow an 1/8-inch gap for expansion at each end. Each board should span at least two joist spaces, and cuts should be staggered with those of neighboring deck boards. Avoid cuts that would leave knots at the ends of the board.

Apply Stain (optional)

Applying paint or stain can add years of service life to new deck boards. It will also help the new boards blend in with any old deck boards. If you’re using wood that accepts stain/paint poorly – as is typical of pressure-treated wood – you may need to allow the boards to dry for several weeks before you coat them. Sanding the boards can also help the stain/paint to adhere. Be sure to coat the end grain of the boards. For a weathered look that matches the existing boards, combine one (1) cup of baking soda with one (1) gallon of water, scrub the solution into the wood, and rinse it off. Allow the board to dry before you coat and install it.

Install the New Deck Boards

To prevent cupping, install the new boards bark side up, so that the grain pattern is convex. Use 3-1/2-inch deck screws to fasten the boards. Drilling pilot holes will make the job easier and help to prevent splitting, especially at the board ends. When placing the new boards, make sure there is a uniform gap between each adjacent board.

How to Avoid, Prevent & Repair Deck Joist Rot

Rotted deck joists can cause homeowners headaches. Learn more about how to avoid, prevent and repair deck joist rot at Decks.com.

How to Prepare & Protect Your Deck for Winter

Preparing and protecting your deck for the cold weather is important to ensure the longevity of your deck, especially in cold climates. Learn how to prepare your deck for winter at Decks.com.

Capped Composite Decking

What is capped composite decking? It's a great option if you like the look of wood but not the maintenance. Learn about capped composite at Decks.com.

Composite vs Wood

We break down the pros and cons of composite and wood decking to help you pick the best fit for your backyard build.

Fiberon

Fiberon low maintenance decking is manufactured by Fiber Composites, LLC in New London, NC

More Helpful Resources

Explore Articles by Topic

Footings

Information related to installing frost footings for decks

Framing

Learn structural framing methods

Decking

Learn about wood and composite decking materials

Stairs

An in-depth look at the complex issue of how to build stairs

Railings

How to install guardrails and handrails to meet IRC code

Features

An overview on water drainage, benches, planters and lights

Design

The basics of deck design

Planning

Learn about permits and working with contractors

Porches & Patios

Build a covered deck to enjoy all seasons

Ledger

Proper attachment techniques

Care

Maintain your deck to maintain your investment

Materials

An overview on water drainage, benches, planters and lights

How to Remove Scuffs and Scratches from Composite Decking

Removing scuffs and scratches can help make your composite deck look like new. Learn how to fix and prevent your composite deck from future scratches.

What is Wet Rot and How Do You Treat It?

Wet rot occurs when water or high moisture levels cause wood to decay. Learn how to recognize the signs and causes of wet rot and how to treat it.

How to Ink Stamps from Pressure Treated Lumber

Ink stamps seen on pressure treated wood represents where the lumber came from and its grade. Learn a few tricks to remove this ink from your wood at Decks.com.

Is Trex Decking Worth the Investment? Expert Insights and Reviews

Discover why Trex decking is worth the investment. Learn about its durability, low maintenance, eco-friendliness, and the long-term value it adds to your home.

Endeck

Endeck PVC decking is manufactured by Enduris Extrusions in Jacksonville, FL.

Explore Articles by Topic

Footings

Information related to installing frost footings for decks

Framing

Learn structural framing methods

Decking

Learn about wood and composite decking materials

Stairs

An in-depth look at the complex issue of how to build stairs

Railings

How to install guardrails and handrails to meet IRC code

Features

An overview on water drainage, benches, planters and lights

Design

The basics of deck design

Planning

Learn about permits and working with contractors

Porches & Patios

Build a covered deck to enjoy all seasons

Ledger

Proper attachment techniques

Care

Maintain your deck to maintain your investment

Materials

An overview on water drainage, benches, planters and lights